How do plastic pallet China manufacturers reduce production costs?

Aug 03, 2023|

Aug 03, 2023| View:179

View:179Every time a plastic manufacturer develops a new product, it must develop a new mold to meet the production requirements. However, the cost of the mold is not low. To reduce the cost of mold opening can only increase the production volume of the product. So what methods can plastic manufacturers use to increase production? Quantity, reduce production costs?

1. Plastic manufacturers should try their best to enrich their product categories, and through market research, prepare some product stocks with large demand to meet customer needs.

2. The design of standardized products not only meets the needs of customers, but also reduces the purchase of raw materials and costs.

3. Some customers may purchase plastic products for the first time only out of trial, so the purchase volume is small, and plastic manufacturers often do not pay much attention to these customers with small purchase volume, resulting in missed opportunities for subsequent large-volume orders. Therefore, plastic manufacturers should pay attention to the needs of every customer.

4. Set up a plastic mold allocation center, and idle molds can be rented from each other, which reduces the cost of mold opening for manufacturers, and also avoids the risks brought by small orders.

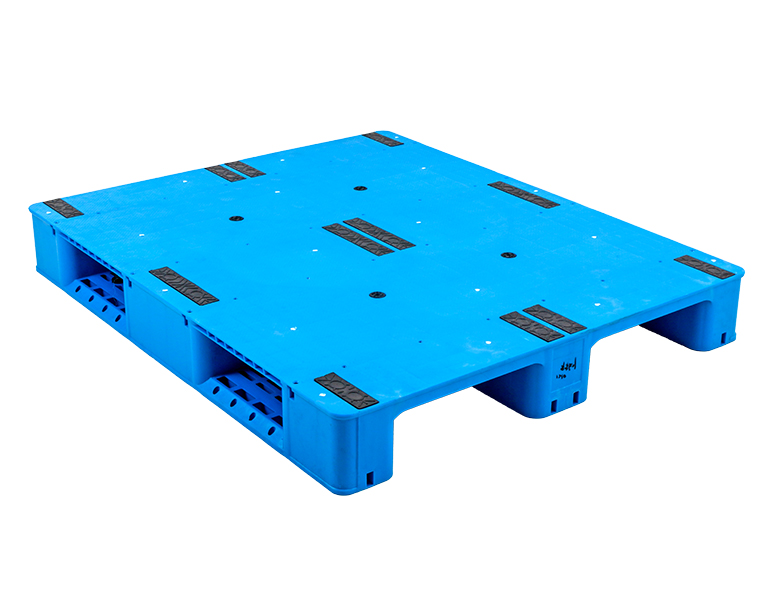

Jiangsu Xuansheng Plastic Industry Technology Co., Ltd. is a professional manufacturer of R&D, production and sales of plastic pallets china and plastic turnover boxes. Welcome to contact us for consultation.

中文

中文