What are the important design details for leak-proof plastic pallets?

Feb 03, 2023|

Feb 03, 2023| View:116

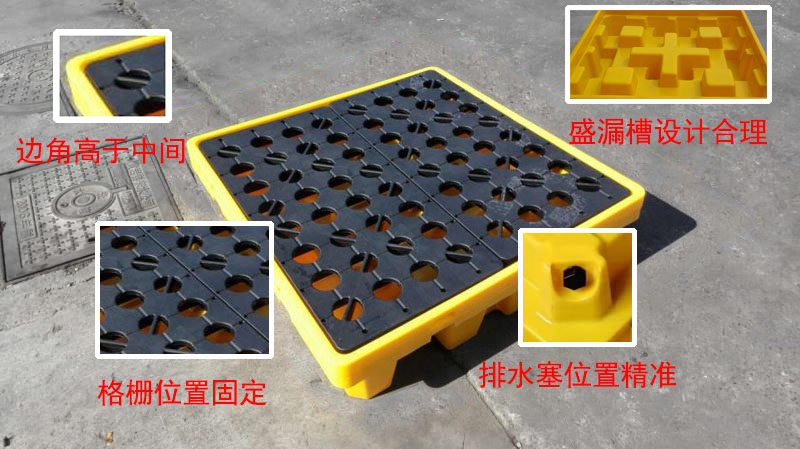

View:116As the name suggests, the anti-leakage tray is a tray that prevents liquid leakage, so the amount of leakage is a very important part. Some unscrupulous merchants blindly imitate other people's high design leakage capacity regardless of the carrying capacity, and have an empty appearance. In fact, the internal leakage tank is completely unreasonable.

Secondly, the design of the drain plug is also a crucial part. The function of the drain plug is to drain the leaked liquid. A good design can drain all the leaked liquid. An unreasonable design of the drain plug can only drain part of the liquid or even not drain the liquid. More importantly, the drain plug must fit perfectly with the tray during production, otherwise there will be a risk of falling.

The oil barrel needs to be placed on the surface of the anti-leakage tray at an angle to prevent the accumulated water on the lid from flowing into the barrel. Therefore, the four corners of the tray should be higher than the middle part to achieve a slight tilt angle.

The two grilles in the middle of the anti-leakage tray should be high, non-slip, and easy to replace. The most important thing is that the grilles should be fixed in the tray slot. It is unsafe to slide randomly, so the tray should be designed Precisely consider the position of the grille.

Jiangsu Xuansheng Plastic Industry Co., Ltd. has been engaged in R&D, production and sales of anti-leakage trays for many years. Welcome to contact us.

中文

中文